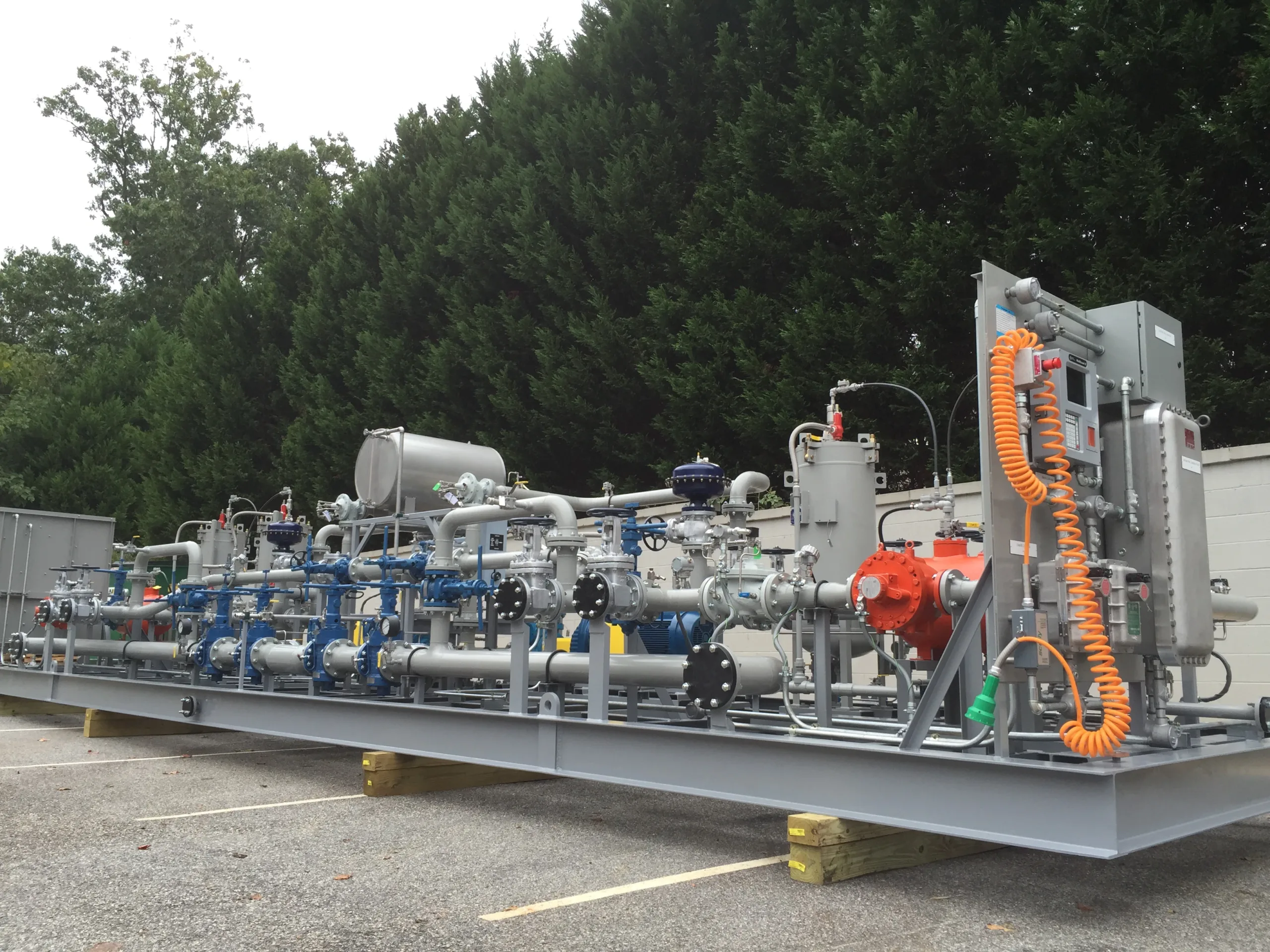

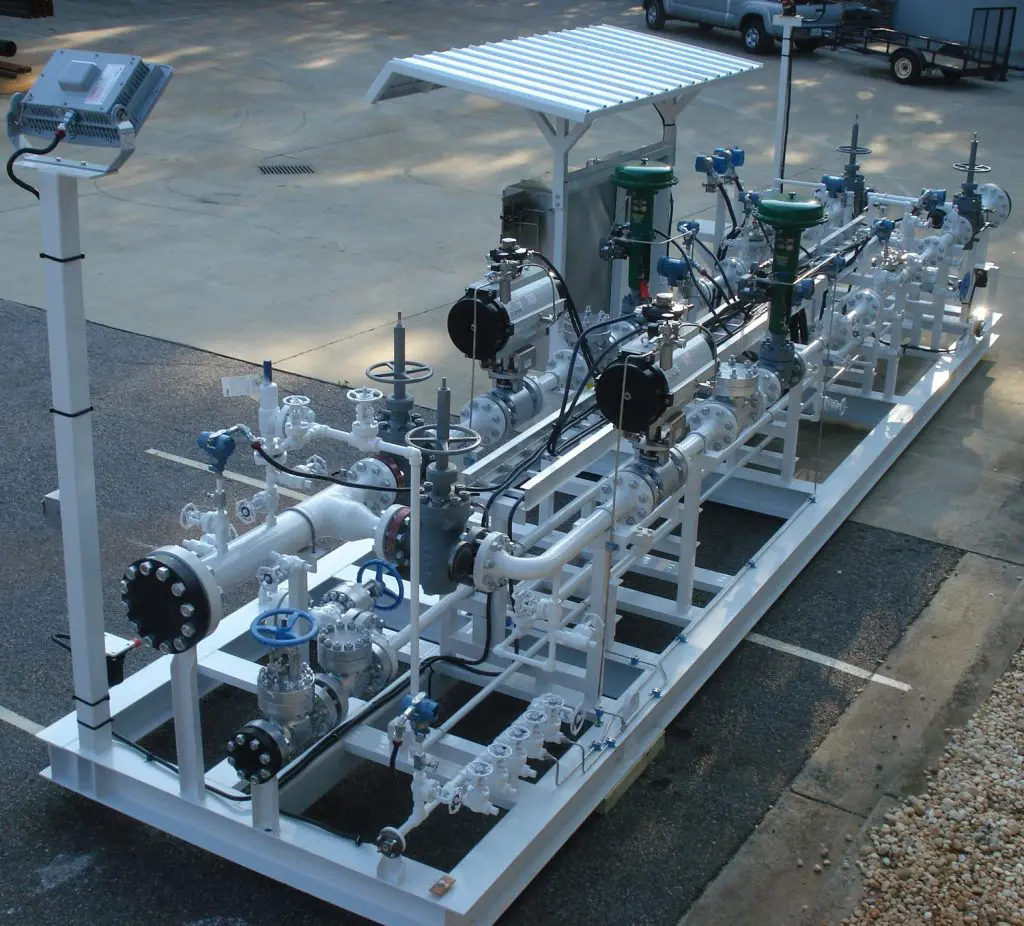

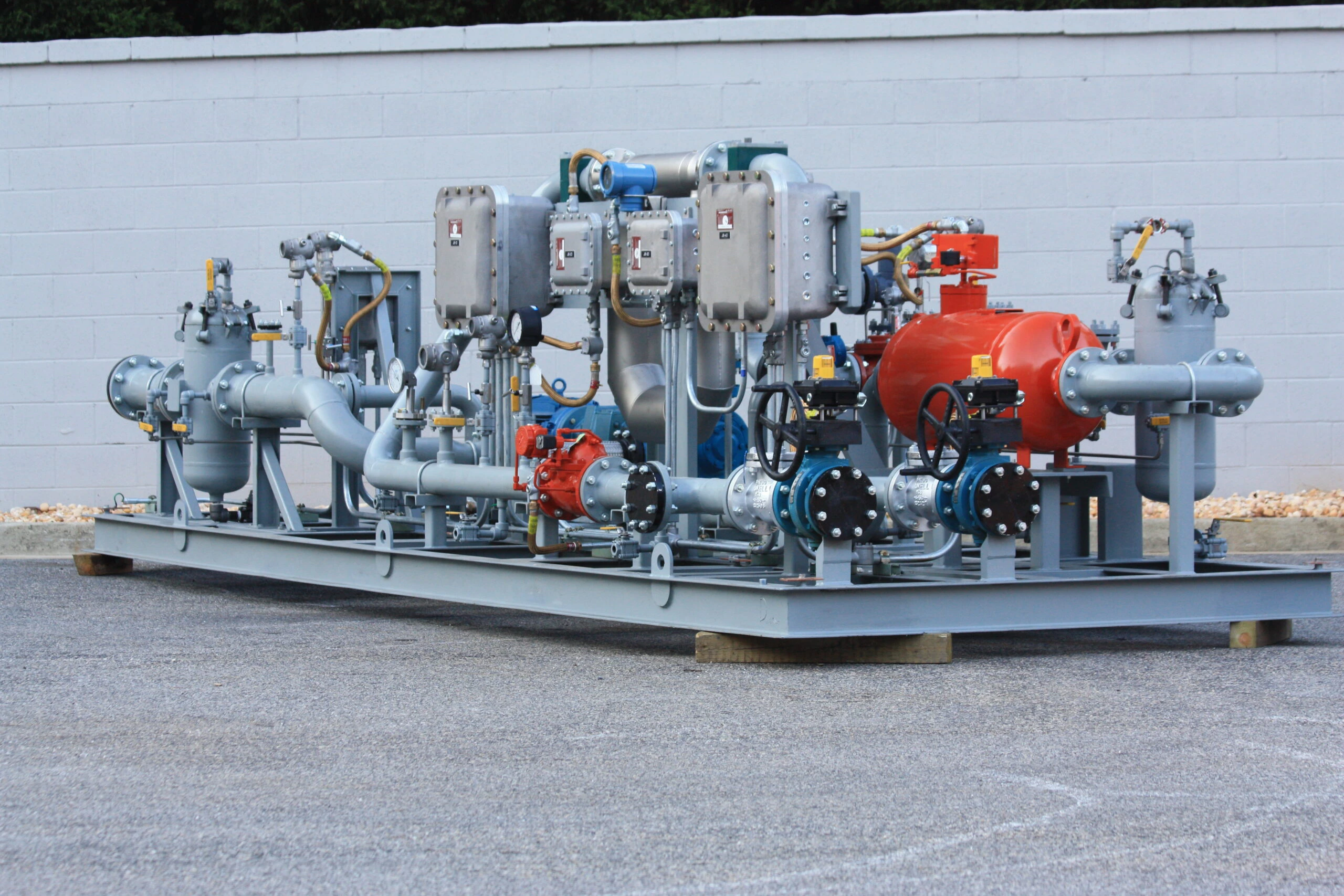

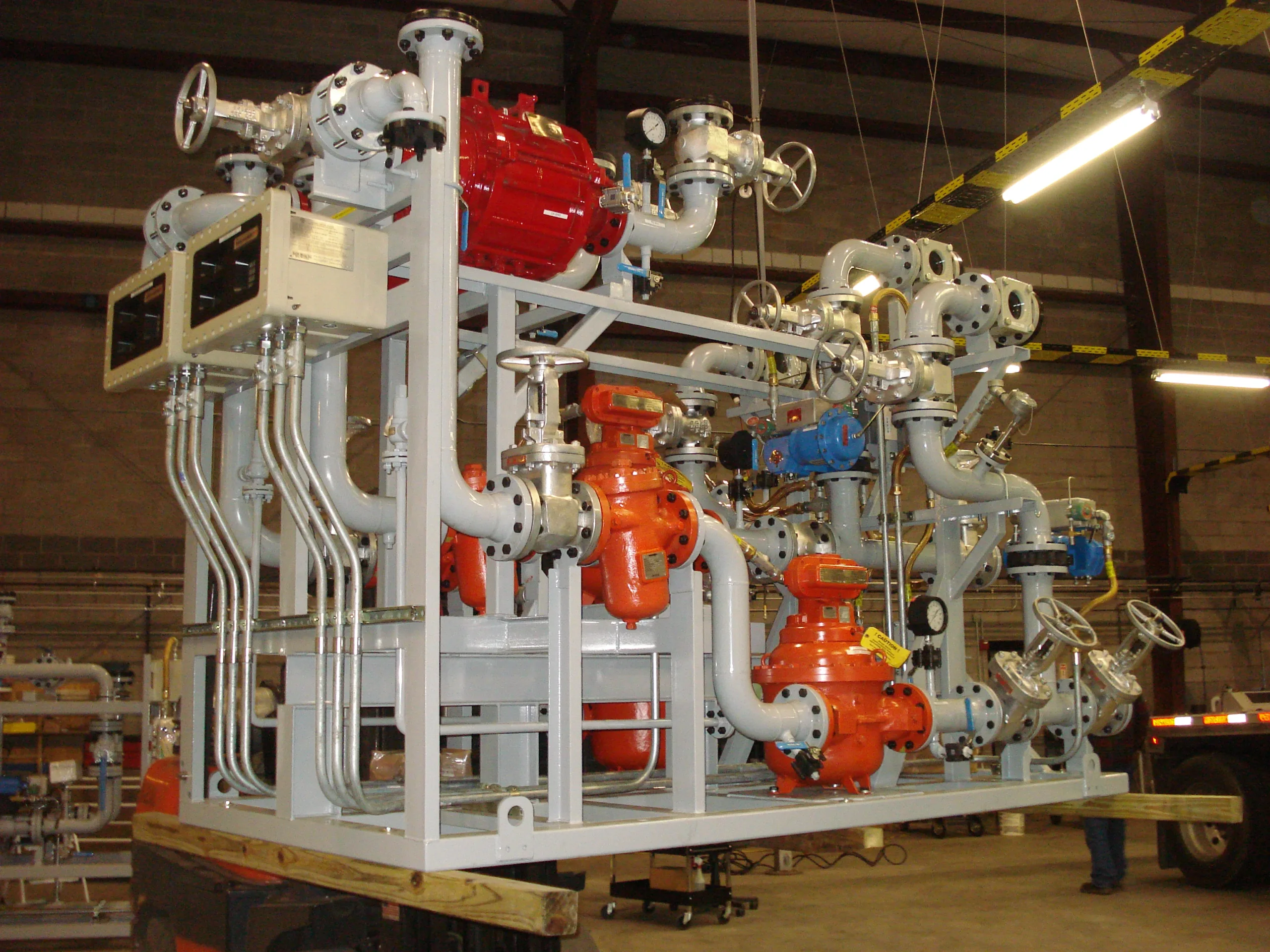

Custody Transfer Skids

At PumpingSol, we specialise in designing and delivering Custody Transfer Metering Skids that align precisely with your project requirements while adhering to industry and government standards, including API guidelines. Our turn-key solutions ensure swift and hassle-free jobsite installations.

Precision and Compliance

At PumpingSol, we pride ourselves on delivering Custody Transfer Metering Skids that not only meet but exceed industry and government standards, including API guidelines. Our commitment to precision and compliance ensures that your custody transfer processes remain seamless and hassle-free.

Turn-Key Solutions for Efficiency

When your job demands a complete, skid-mounted Custody Transfer Metering system for quick and easy jobsite installation, PumpingSol has the experience and capabilities to deliver turn-key solutions. We understand that time is money, and our systems are designed to minimize installation time, saving you valuable resources.

Ensuring Accuracy for Profit

Precise measurement of crude oil, alternative energy fluids, natural gas liquids, gaseous products, and other fluids during custody transfer is critical to your bottom line. Variations in temperature can lead to changes in density, potentially resulting in significant monetary losses for both sellers and buyers. PumpingSol ensures that our Custody Transfer Metering Skids are engineered to mitigate these risks effectively.

Calibration Excellence

To solidify our commitment to precision, PumpingSol is a worldwide leader and supplier of flow meters to the process and petroleum industry. We’ve been involved in the design and fabrication of a calibration system for coriolis-type flow meters. We understand that accuracy of measurement is crucial for custody transfer applications, and our solutions reflect this commitment.

Tailored to Your Needs

Client-specific application requirements are paramount when designing and building Custody Transfer Metering Skids. Our approach revolves around providing solutions that precisely match your needs. Additionally, compliance with governing body regulations such as ISO, API & AGA and metrology standards such as NIST, GOST, OIML, ONML, PTB, CMC are integral factors in system design and cost considerations.

Collaborative Problem-Solving

If you have a general idea of your project goals but are uncertain about the specifics, don’t hesitate to reach out to one of our experienced sales engineers. We may have a standard solution available for quick turnaround that aligns perfectly with your project requirements.

Contact Us Today

Whether you have a liquid or gas Custody Transfer application, PumpingSol is your trusted partner. Discover why our customers become long-term partners who keep coming back. We extend a warm invitation to take the next decisive step in elevating your operations. Contact us at (770) 740-8866 or send an e-mail. Our team of seasoned experts eagerly awaits your inquiry, ready to engage in a personalised consultation. This is your opportunity to articulate your specific needs, challenges, and aspirations. Reach out today, and let us embark on a transformative journey to enhance your operations, amplify profitability, and fortify reliability.