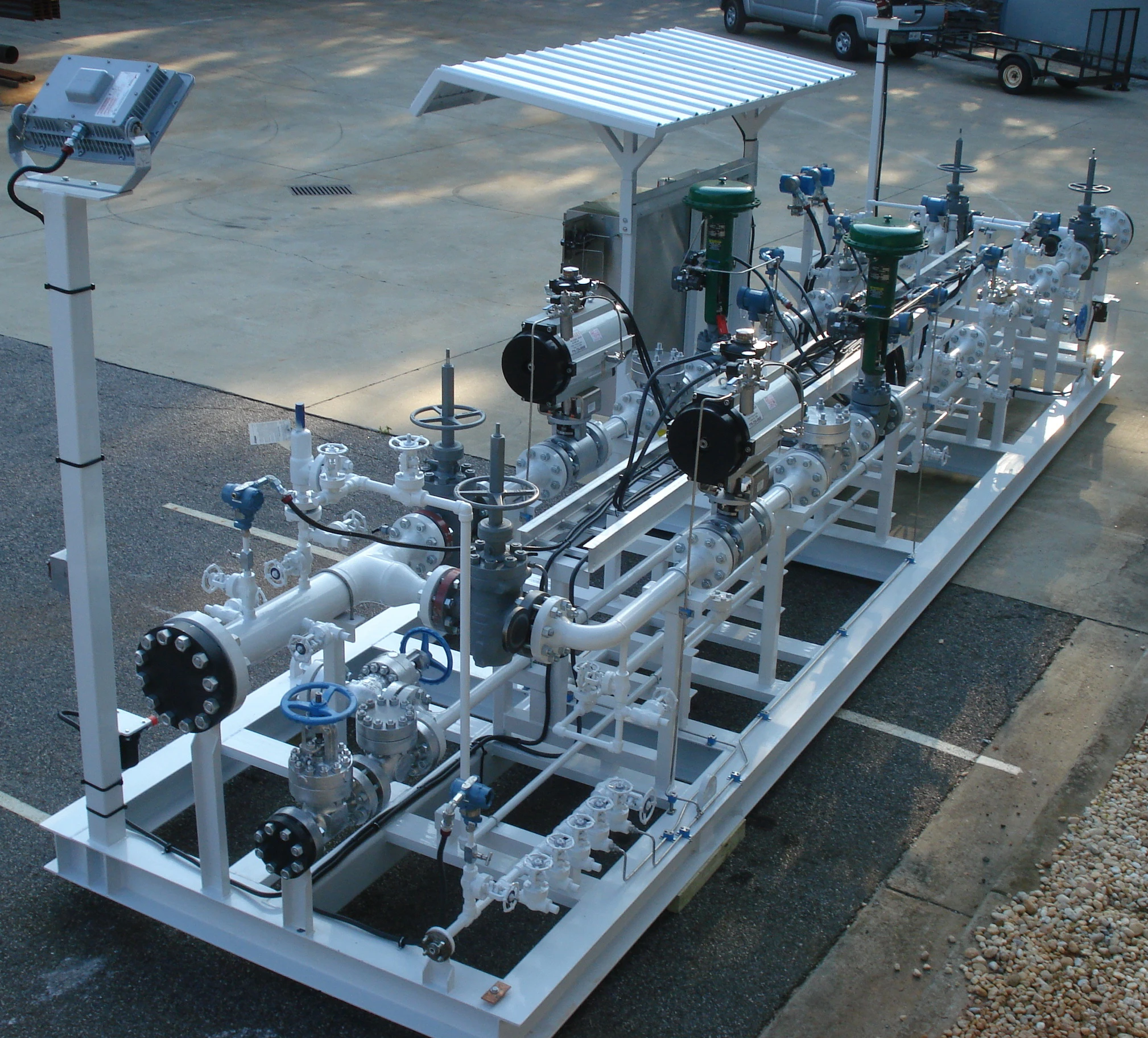

Fluid Loading Skids

In today’s rapidly evolving world, where millions of individuals are gaining access to personal vehicles and enjoying improved lifestyles, the demand for crude oil and hydrocarbon derivatives is skyrocketing. To meet this ever-growing demand, PumpingSol stands at the forefront, offering innovative solutions in the form of fluid loading and unloading skids for both trucks and rail-cars. We understand the critical importance of efficient fluid handling in the oil and gas industry, and our mission is to provide top-tier solutions that are optimized for performance, reliability, and ease of use.

Proven Expertise and Customization

At PumpingSol, we take pride in our ability to deliver a wide range of fluid loading and unloading skids promptly. Whether you require a standard design package with off-the-shelf components or a customized solution tailored to your specific needs, we’ve got you covered. Our team has a proven track record of designing and manufacturing skids and control systems for truck unloading and measuring terminals, all under one roof. This approach not only ensures quality but also saves valuable time for our clients.

Engineering Excellence

Our team comprises exceptional individuals, each a specialist in their respective fields. From seasoned process and mechanical engineers to electrical engineering experts, we possess a wealth of knowledge and experience in designing fluid loading and unloading skids. We harness the power of cutting-edge 3-D design CAD software and advanced systems analysis to craft solutions that are both efficient and reliable. Our proficiency extends to PLC and electrical control systems, making us well-versed in handling various fluid types.

Comprehensive Solutions

PumpingSol has a rich portfolio of systems that cater to diverse needs within the oil and gas industry. Some of our offerings include custody transfer fluid systems for hydrocarbons, truck unloading skids for light crude, diesel, and petroleum derivatives, and complete truck unloading terminals with multiple bays. Each skid seamlessly integrates with our terminal control systems, encompassing components like MCCs (motor control center), PLCs, HMIs (human machine interface), flow computers, and operator PCs. This harmonious synergy ensures a flawless operation from unloading to the final destination, that includes tank farms and pumping booster stations for moving the crude oil to refineries or to the ports.

Quality Manufacturing

Our manufacturing team consists of a select group of technicians who possess extensive knowledge of both mechanical and electrical controls. Certified according to AWS standards, our welders utilize modern robotic welding and automated cutting machinery, ensuring precision and consistency. We are committed to maintaining the highest quality standards and possess ISO 9001 certification. Every component used in PumpingSol-built fluid loading and unloading skids is sourced from reputable manufacturers, guaranteeing trouble-free installation and long-term reliability.

Rigorous Testing

Before leaving our facility, all PumpingSol-built fluid loading and unloading systems undergo rigorous testing. Our engineers and technicians simulate real-world scenarios, running fluids through each skid individually. This meticulous testing ensures that our equipment performs flawlessly when it matters most – in the field.

Client-Centric Approach

At PumpingSol, we believe in going the extra mile for our clients. We invite them to our facility to witness their equipment in action, provide training, and make any final adjustments based on their preferences. We are committed to ensuring our clients are fully satisfied with their new fluid loading and unloading systems or skids.

Seamless Commissioning

Once the system is installed, piped, and connected at the local terminal, PumpingSol deploys qualified engineers to assist with startup and fine-tuning. Thanks to our exhaustive in-house testing, we streamline the field startup and commissioning process, saving our clients precious time and resources.

Contact Us

To find out more about our packaged pumping systems click on the link below or call one of our Sales Engineers at (770) 740-8866.