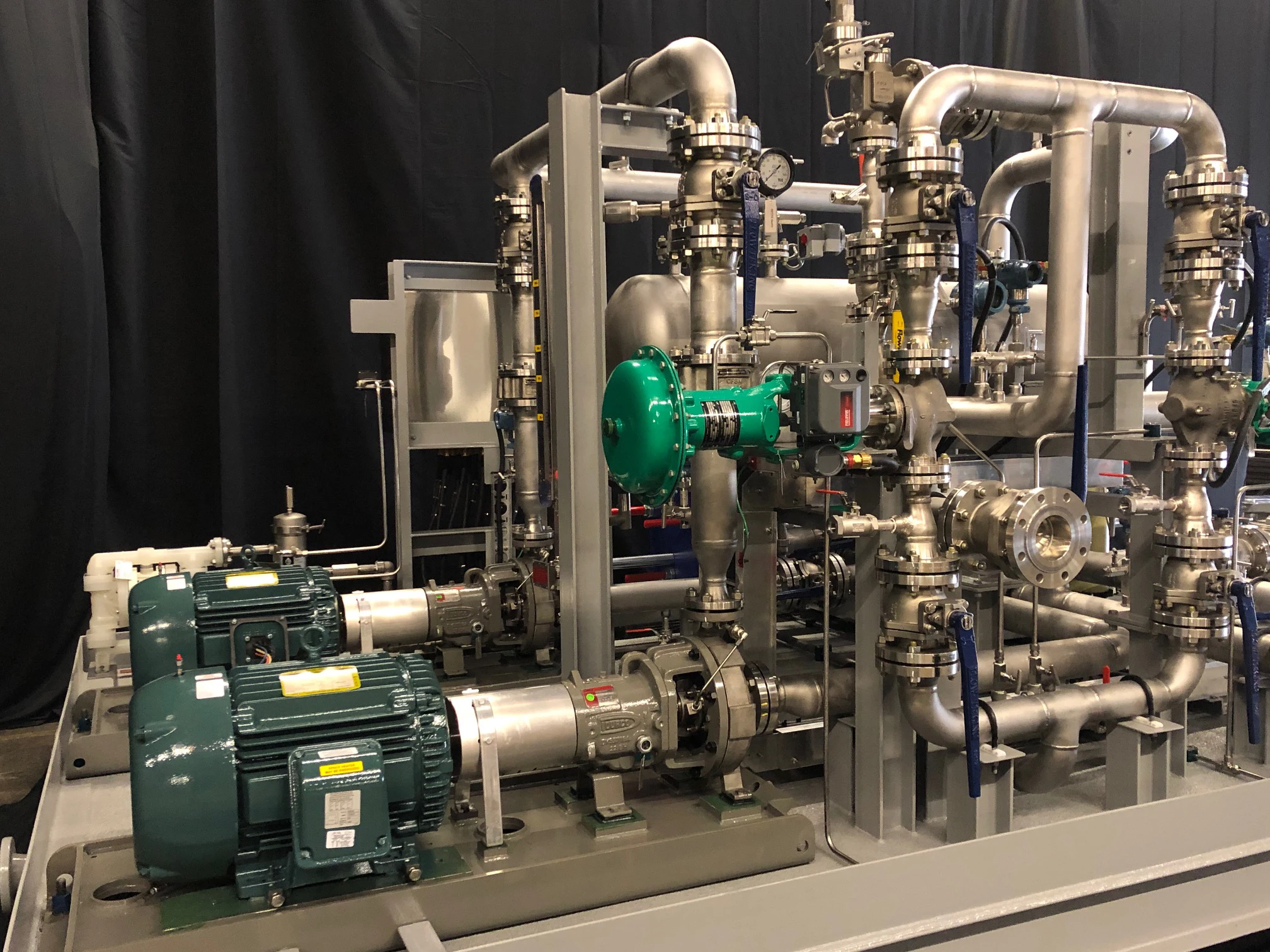

Cooling Skids

When it comes to designing cooling pumping skids tailored to your specific needs, the engineering team at PumpingSol stands ready to deliver exceptional solutions. With a wealth of experience in cooling skids for large industrial electrical panels, cooling of process equipment, power generation, and mining, you’ve come to the right place for all your cooling skid requirements.

Unparalleled Expertise and Flexibility

The knowledge and expertise of our design team enable us to be highly flexible and adaptable in crafting solutions that precisely match your needs. Leveraging cutting-edge technologies, we tailor your cooling pump skid to your unique requirements. Many industrial, mining, or commercial processes generate excess heat at various stages, making cooling skid systems a critical component. These systems excel at removing excess heat while ensuring the cleanliness of the heat transfer fluid throughout the system’s lifespan.

Environmental and Noise Considerations

In today’s world, environmental concerns and noise regulations play a crucial role in equipment selection. Our engineers at PumpingSol have extensive experience in accommodating process needs while addressing even the most stringent noise or environmental requirements. We ensure that your cooling skid operates efficiently while adhering to all local regulations.

Enhanced Performance with De-Ionizing Systems

For applications demanding the highest level of coolant purity, our cooling skids can incorporate de-ionising systems. These systems are designed to remove the smallest impurities from the water-coolant mixture, reducing coolant conductivity and enhancing the entire cooling system’s reliability.

Comprehensive Monitoring and Control

Maintaining precise temperature ranges and water-coolant quality standards is paramount. Our cooling skids come equipped with all the necessary process instrumentation to monitor and control these parameters. For critical processes that cannot afford downtime due to cooling system failures, most of our skids feature redundant pumps and instrumentation.

Integrated Control Systems

At PumpingSol, we offer fully integrated control systems within the cooling skid boundaries. Our controls utilize PLC and HMI solutions, ranging in complexity to match your specific requirements. Rest assured that all our systems undergo rigorous in-house design, testing, and FAFT (factory acceptance floor test) before shipping, ensuring top-tier quality and reliability.

Contact Us Today

For more information about our Cooling Skids and to discuss how PumpingSol can meet your cooling system needs, please contact our Sales Engineers at (770) 740-8866 today. We look forward to assisting you in achieving optimal cooling performance for your operations. Trust PumpingSol for excellence, reliability, and unmatched quality in cooling skid solutions.