Deionized Water Cooling Systems

Welcome to PumpingSol, your trusted partner in delivering high-quality deionized water cooling solutions for critical industrial, chemical, power generation, mining, and marine applications. Our expertise in low conductivity water systems ensures efficient heat transfer, minimal downtime, and precise control. As a professional in your industry, you understand the importance of reliability and performance in cooling systems, and that’s precisely what we offer.

The Significance of Deionized Water

In many heat transfer applications, the use of low conductivity water is imperative. This specialized water, known as deionized (DI) or demineralized (DM) water, undergoes rigorous purification processes to remove cations and anions, greatly reducing its electrical conductivity. The removal of minerals and impurities is vital, as tap, stream, lake, sea, and industrial process waters often contain minerals that can compromise the cooling process.

Higher conductivity water not only jeopardizes the integrity of electronic components but also leads to scale buildup, corrosion, and erosion. Therefore, for mission-critical cooling in industrial, chemical, mining, marine, and power generation applications, deionized water, either treated or mixed with glycol, becomes indispensable.

System Redundancies and Downtime Mitigation

Recognizing the critical nature of applications requiring deionized water, we prioritize system redundancies and downtime prevention in our cooling system designs. Our solutions are engineered for continuous monitoring and precise control of deionized cooling water conductivity levels and process temperature ranges.

Moreover, we address the potential challenges posed by the introduction of very low-temperature deionized cooling water into the process equipment. This can result in external condensation on piping and instrumentation, increasing the risk of catastrophic equipment failure due to electrical short circuits. Our designs take into account these nuances, ensuring your operations run seamlessly and without incident.

PumpingSol’s Expertise in Low-Conductivity Water Systems

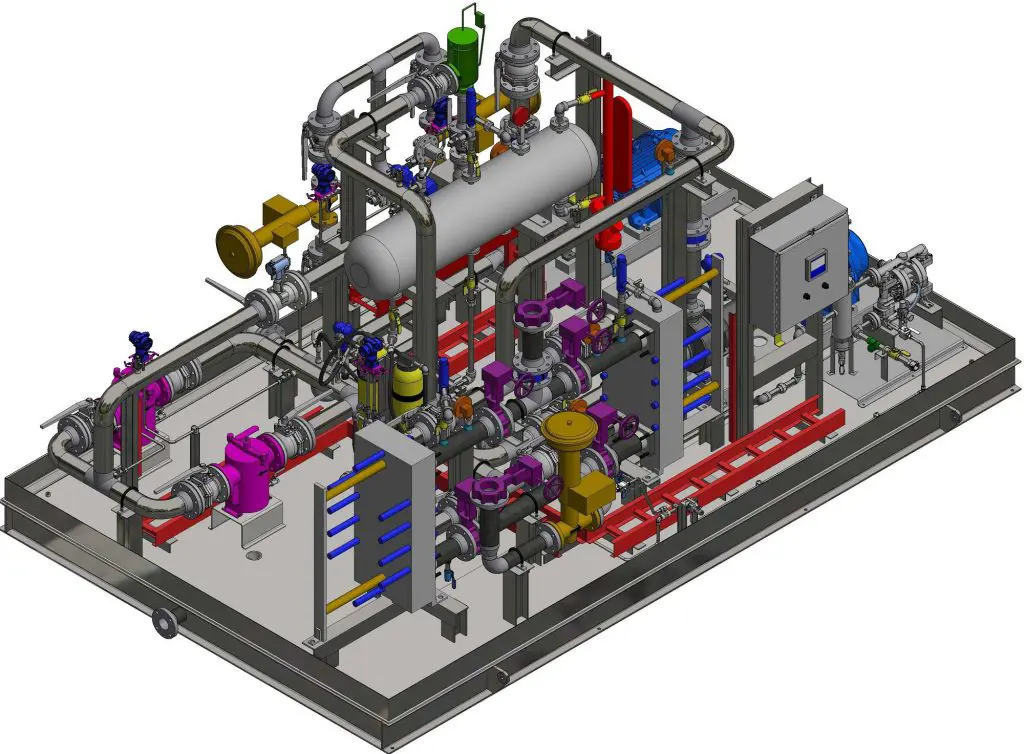

PumpingSol boasts a track record of designing and constructing low-conductivity water skid-mounted heat transfer systems. Our expertise extends to various cooling methods, including air-to-water and water-to-water heat exchangers, as well as evaporative cooling towers for cooling non-contact process water.

Our team has successfully engineered, built, and tested both single-loop and dual-loop deionized water cooling systems. These systems cater to diverse requirements and applications, offering versatility and reliability.

Single Loop Heat Transfer Systems

In single-loop systems, we employ air-to-water heat exchangers. Here, outside air is used to cool the deionized water via liquid heat transfer coils and forced air. Alternatively, we can utilize a plate & frame heat exchanger (water-to-water) to tap into available plant (non-contact) water for cooling the deionized water.

Dual Loop Cooling Systems

Dual-loop cooling systems consist of two distinct circuits. The first is the “clean water” (deionized water) loop, which cools the process equipment through a plate & frame heat exchanger. The second is an outside “non-contact” water cooling loop, which extracts heat from the “clean water” circuit and transfers it to an evaporative cooling tower. This highly efficient design optimizes heat removal from the process.

Sizing Your Cooling System

When sizing your low conductivity cooling water skid system, we consider critical parameters, such as:

Additionally, we address system-specific challenges and variables, including:

Our team of experienced engineers and technicians collaborates closely with your team to tailor the ideal low conductivity cooling water skid system for your unique process and location.

Our Proven Track Record

PumpingSol takes pride in delivering reliable solutions. We have manufactured several deionized water cooling skid systems installed throughout North and South America, with some in operation for over a decade. Our commitment to excellence has forged long-term partnerships with satisfied clients.

Contact Us Today

Give team PumpingSol the opportunity to assist you in designing and executing your next low conductivity cooling water skid system. Experience the difference in performance and reliability that sets us apart. Contact us today at (770) 740-8866 to discuss with our in-house engineers your specific requirements and discover why we are the preferred choice for deionized water cooling systems.