Heat Transfer Skids

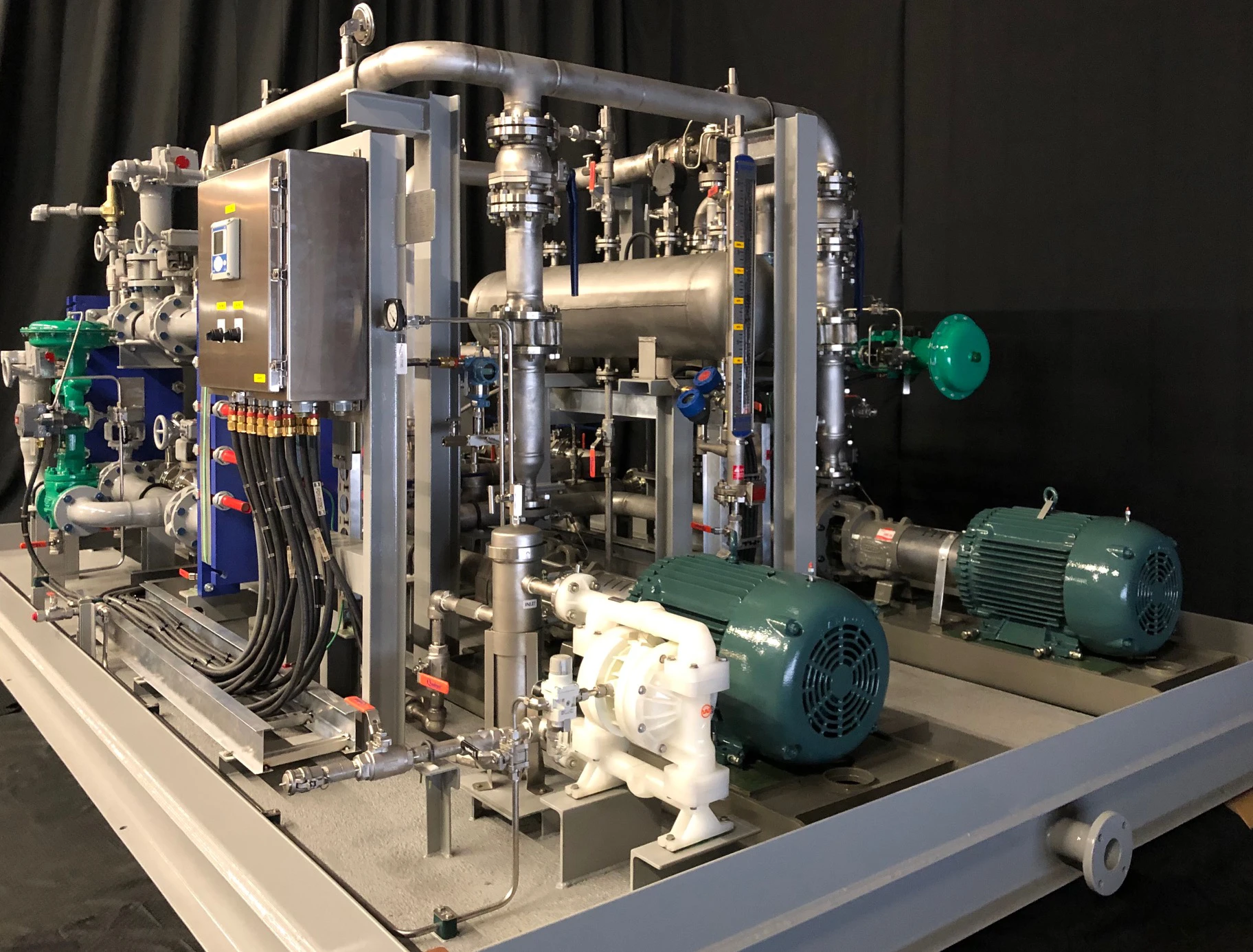

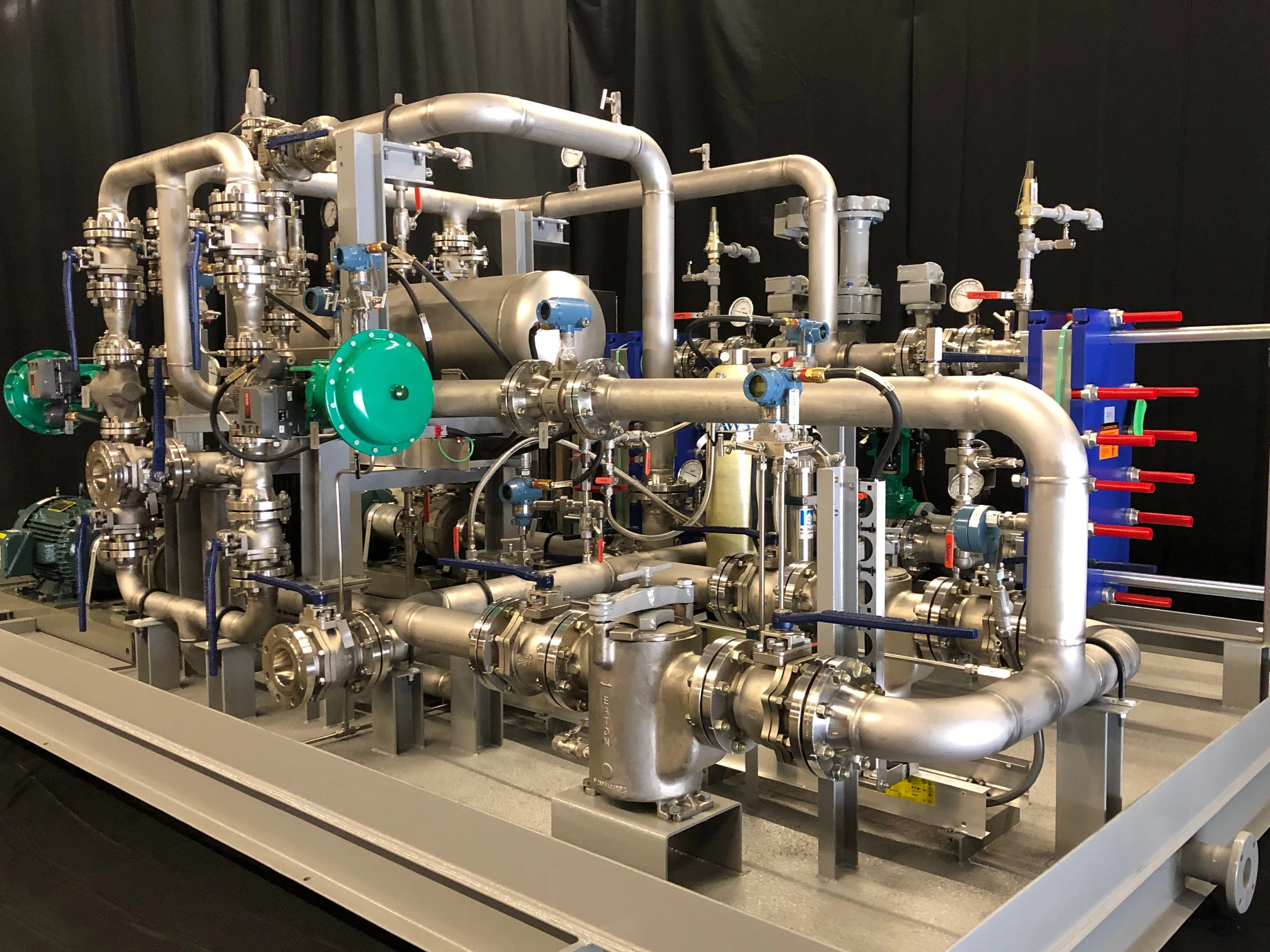

Welcome to PumpingSol’s Heat Transfer Skids, where innovation meets precision engineering. With a wealth of experience and expertise, we specialise in designing skid-mounted heat transfer systems tailored to your specific application requirements. Our commitment to excellence ensures that every Heat Transfer Skid we provide not only meets but exceeds your expectations. Our Heat Transfer Skids are delivered completely pre-assembled and tested, making installation and start-up a breeze. Discover how our systems can elevate your operations.

Engineering Excellence

Our Skid Mounted Heat Transfer Systems are meticulously engineered to your specifications, ensuring that they precisely align with your unique needs. Whether you require hot water, glycol-mix steam, hot oils, or snowmelt applications. We take pride in delivering solutions that are tailored to your exact requirements, providing you with the best possible performance.

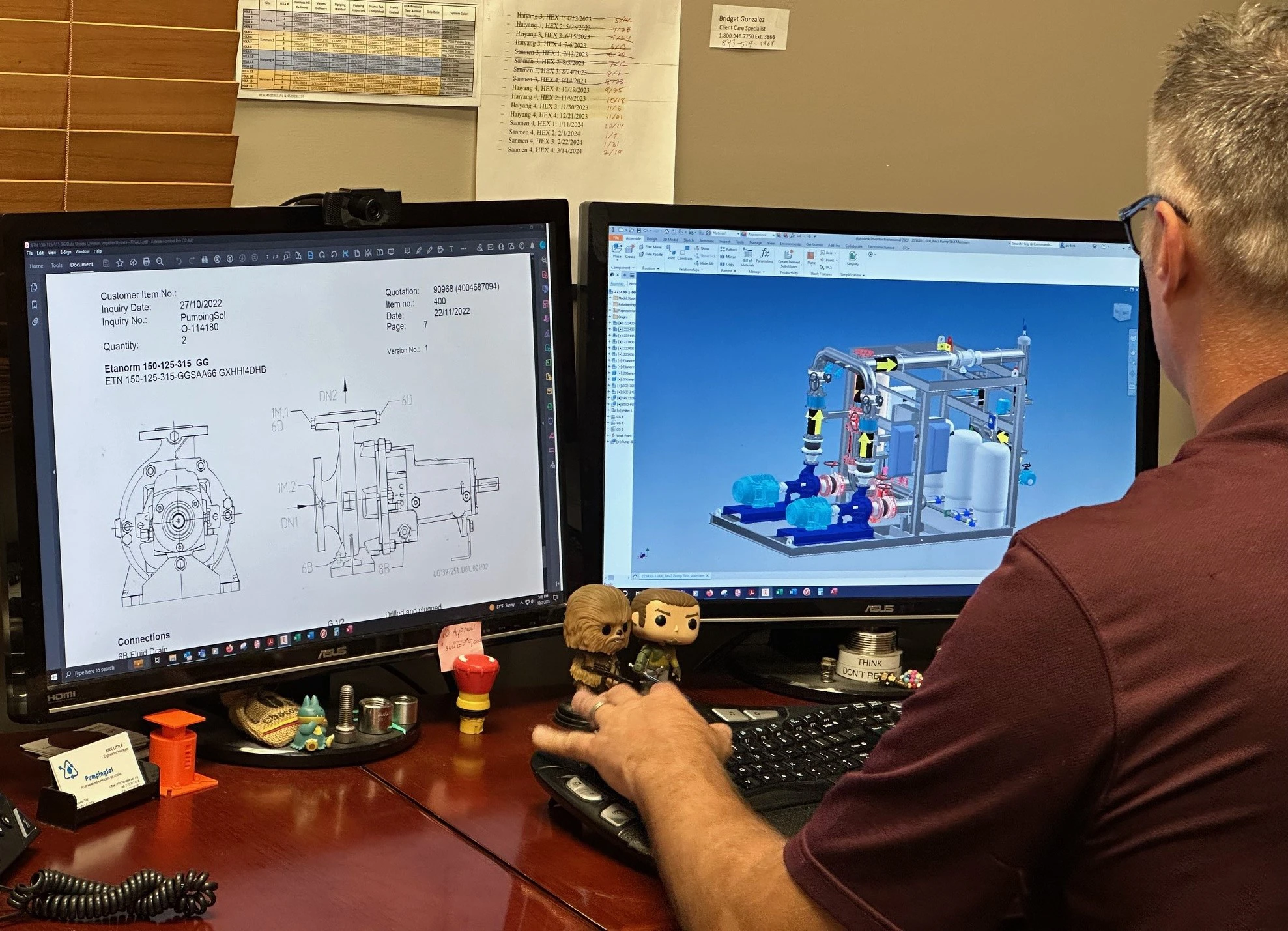

Expert Engineering Team

Our in-house engineering team boasts extensive experience in pumps, heat exchangers, piping, and controls. With their skill and knowledge, they ensure that every skid-mounted system is not only well-designed but also functionally tested before shipment, guaranteeing optimal performance.

Versatile Materials

We work with a wide range of materials, including carbon steel, stainless steel, alloy 20, copper, brass, and aluminum, ensuring that the components of your heat transfer system are of the highest quality. Our pipe work options include threading, flanging, compression, or welding, and our ASME B31-3 certified welders ensure precision.

High Purity Water Cooling System

Incorporated de-ionizing systems in our heat transfer skids remove even the smallest impurities from the water-coolant mixture. This significantly reduces conductivity and enhances the reliability of the entire heat transfer system. Moreover, our skids come equipped with instrumentation to monitor and maintain temperature ranges and water-coolant purity standards, especially in critical applications.

Integrated Control Systems

PumpingSol offers fully integrated control systems within the boundaries of our Heat Transfer Skids. From basic controls to complex PLC and HMI integrated solutions, our systems are designed, tested, and fine-tuned in-house by our team of engineers and technicians. We also provide comprehensive FAFT (factory acceptance floor test) services to our clients.

Contact Us

Ready to elevate your heat transfer system to new heights of efficiency and reliability? Contact PumpingSol today to speak with one of our experienced engineers at (770) 740-8866. Discover how our Heat Transfer Skids can optimise your processes and exceed your expectations. At PumpingSol, precision engineering is our promise, and innovation is our tradition. Choose us for the solutions that set the industry standard.