Custom Control Systems

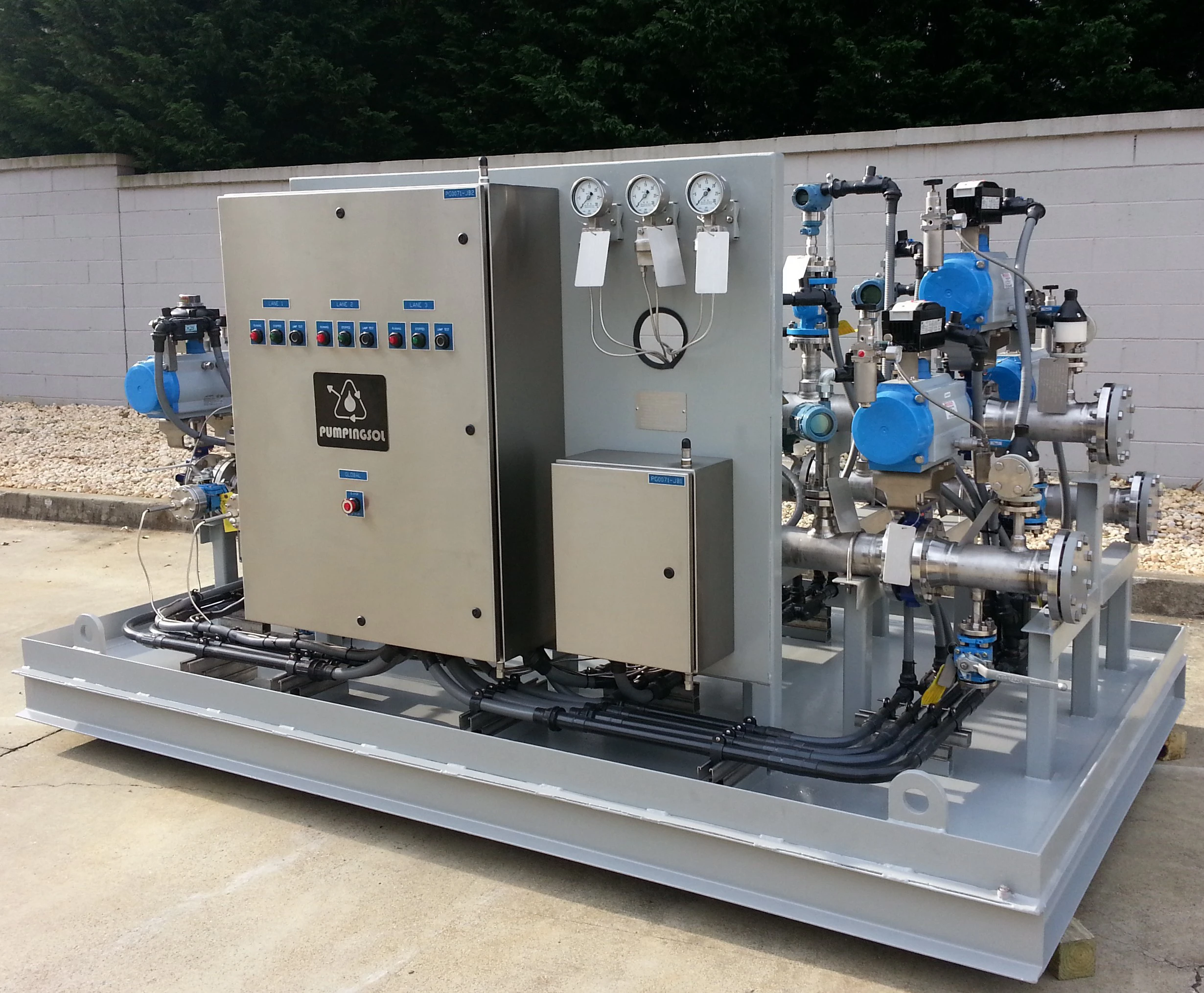

At PumpingSol, we stand as your sole source supplier for all your fluid handling requirements. In addition to our robust mechanical engineering and manufacturing capabilities, we boast highly qualified electrical engineering and fabrication departments.

Custom Control Systems Crafted to Perfection

Our electrical engineers possess the expertise required to design and implement custom control systems, guiding you from initial concept through installation and providing unwavering support throughout your equipment’s lifecycle. With a wealth of experience, insight, and dedication to your goals, our engineers ensure your success not only at the start but throughout the entire equipment lifecycle.

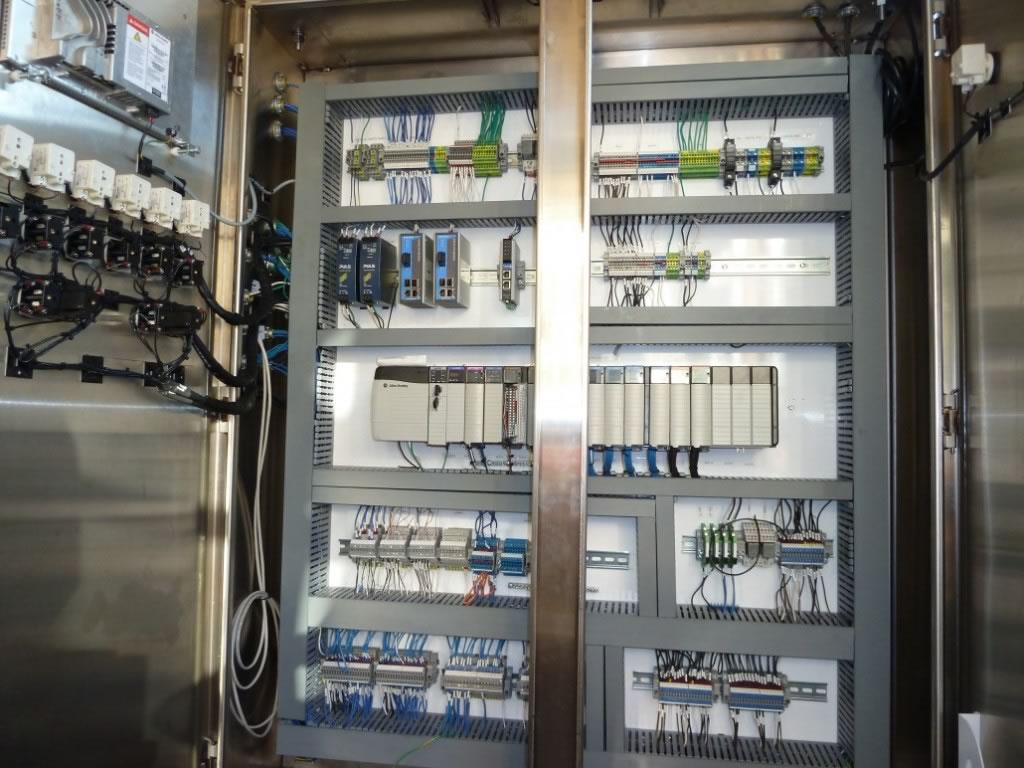

Control Systems

Our control systems are designed with precision, often utilizing Allen Bradley programmable automation controllers (PAC’s) such as CompactLogix or ControlLogix. However, we’re equally adept at providing customer-specified solutions, employing a variety of programmable controllers, including Allen Bradley SLC500, PLC5, Siemens S7-200, S7-300, ABB AC500 series, Mitsubishi FX series, Omron CQM1, Koyo DL305 (Formerly GE “Series One”), GE Series 90/30, and more.

Meeting and Exceeding Industry Standards

All control panels are meticulously assembled and wired to meet or exceed rigorous quality and safety standards. Our commitment extends to conforming with industry standards, including NFPA 70 (National Electric Code) and NFPA 79 (Electrical Standard for Industrial Machinery). If necessary, we can provide UL-inspected panels, fully aligned with any additional customer specifications.

Safety First

Safety is paramount in our skid designs. All wiring within the skid meets or surpasses industrial standards, including NFPA 70 and NFPA 79. For highly flammable and volatile substances, we provide explosion-proof or intrinsically safe wiring, adhering to Class I, Division 2 requirements.

Expertise in Human-Machine Interface (HMI)

Our expertise extends to Human-Machine Interface (HMI) applications tailored to your preferences, seamlessly integrated with the PLC. Our HMI solutions encompass Allen Bradley PanelView, PanelView Plus (including the newer “PanelView 5000” series and “PanelView 800” series), and other options, using relevant development software such as FactoryTalk View Studio ME and SIMATIC ProTool.

Contact Us Today

Give PumpingSol the opportunity to demonstrate why our customers become long-term partners. We’re committed to delivering customized solutions that meet your unique needs, backed by exceptional expertise and support. Your success is our priority. Contact us today to learn more or discuss your specific requirements. Our team of experts is standing by to assist you in finding the perfect solution for your application. Reach out to PumpingSol at (770) 740-8866.